Mobile vs. Fixed Cell Towers — How to Choose, Costs and Time to Deploy

In the U.S., many new macro cell sites cost an average of $200,000 to $300,000, though simpler installations can be less pricey, while complex or specialty sites can exceed $1 million. The exact price will depend on many factors, including the site location, terrain, height, tower type and whether the tower is a fixed or mobile structure. Whether you’re a telecom operator, a public safety agency or a defense contractor, knowing how much it costs to install a cell tower can help you plan and budget appropriately.

This guide examines the factors that influence cell tower costs, enabling you to make an informed decision about your next communications infrastructure investment.

How Much Does It Cost to Build and Install a Cell Tower?

Several factors influence the cost of cell tower installation, including project scope and whether you deploy a fixed or mobile tower. Simple, single-tenant structures can come in under $200,000, while complex, multitenant or specialty installations might cost well over $1 million. Every phase of the process involves expenses, from planning and permitting to construction and final commissioning.

Lower-cost installations usually consist of basic monopole towers in accessible locations. More expensive projects typically involve custom builds in challenging sites or those with advanced security and communication requirements.

Mobile towers typically cost between $70,000 and $250,000, depending on the category, height, antenna load and onboard power systems. You can create a more accurate budget by learning which variables can push a project toward the lower or higher end.

Fixed Tower Type and Height

Towers fall into three categories.

- Monopole: These freestanding tubular towers often take up 2,500 square feet and are 50 to 200 feet tall. They are less expensive, as they need the least amount of land area to build and are the shortest type of cell tower. However, their urban or suburban location means higher land prices while accommodating fewer tenants.

- Lattice: Lattice towers, which take up 2,500 to 10,000 square feet and stand 200 to 400 feet tall, are often in urban, suburban and rural areas. These structures taper from the bottom with multiple legs and open-framed structural supports. Mid-range towers require more real estate and stand taller than monopoles, which drives up labor costs due to on-site assembly. However, depending on the location, lower land prices may offset those expenses.

- Guyed: These cell towers rely on cables secured to anchored footings in the ground for support. Sited in rural areas, they can take up to 20 acres and range from 200 to 2,000 feet in height, requiring higher direct material costs to build. Also, the Federal Aviation Administration usually requires towers 200 feet above ground to have lights, which may add costs. Still, guyed structures offset some of these extra costs by having a higher capacity for more tenants.

Mobile towers are pre-built and can deploy rapidly in emergency response and remote operations. They come in various forms, including cells on wheels, trailer-mounted units and telescopic masts. Built with lightweight aluminum and modular components, these towers are easy to transport, set up and reposition as needed — making them a flexible solution for temporary coverage or infrastructure support. Fixed towers need to be assembled on site.

Tower Materials

Material choice also impacts the cell tower’s final cost. Steel is a standard material known for its strength and cost-effectiveness, often used in macro self-supporting and guyed cell towers. However, aluminum does well for telescoping, mobile and mid-height permanent installations, offering excellent corrosion resistance, weight savings and ease of transport.

While aluminum towers might have a higher initial price tag, they deliver lower maintenance costs and longer service life, making them wise investments for harsh environments or mobile deployments.

Site Acquisition and Preparation

Additional expenses in this phase may include leasing or purchasing land and conducting geotechnical surveys to ensure the ground adequately supports your tower. Site preparation, which includes tasks like clearing vegetation, grading the land and pouring foundations, also increases the total. Additionally, costs can be higher when installing towers in remote areas or sites that are more challenging to access.

Mobile towers require minimal site preparation. Most operate from trailers, skids or prefabricated pads and only need a stable surface, a clear radius for guy anchors as needed and secure staging for power and equipment. The absence of permanent foundations reduces upfront capital and long-term site commitments, allowing rapid deployments across various settings.

Installation and Labor Costs

Labor is a substantial line item in any tower project. Worker salaries can depend on the region, project complexity and your installation team’s experience. Tower design and materials can ensure a smoother installation, with lightweight aluminum usually reducing the labor hours and equipment needs.

Manufacturers design mobile towers for field efficiency. Telescopic masts, trailer stabilizers and simplified grounding may allow technicians to deploy and commission a unit in a single shift.

Permitting and Regulatory Fees

Every tower must comply with local zoning laws, building codes and FAA regulations for tall structures. Consider how permitting fees, environmental assessments and regulatory approvals might add to the budget and extend the project timeline.

Mobile towers often qualify as temporary wireless facilities, which may expedite permitting processes in some jurisdictions. Emergency use or event-specific deployments may benefit from reduced fees and simplified approval processes. While mobile deployments still require adherence to FAA rules, their regulatory flexibility may shorten lead time and lower pre-deployment costs compared to fixed towers.

Calculating the ROI of a Tower Investment

Calculating the ROI of a Tower Investment

Cost matters, but so does the value your tower delivers. Calculating its return on investment will justify the expense and guide better decision-making, depending on your industry.

- Telecom operators: The telecommunications sector measures ROI in increased network capacity, improved coverage and the ability to attract new customers or lease space to other carriers. Mobile towers accelerate network expansion into temporary hot spots and reduce revenue loss during fixed site maintenance.

- Military and intelligence: Communication, security, surveillance and mission-readiness are essential in these fields. Mobile systems provide tactical communication and support the rapid repositioning of nodes to maintain coverage and resilience.

- Public safety: Reliable cell towers lead to faster emergency response times, coordination and resilient communications during disasters. Rapid-deploying mobile systems reduce delays, support incident coordination and may lower costs by enabling immediate on-scene communications.

When you weigh the upfront costs against long-term benefits, you can make more strategic choices to maximize your cell tower’s performance and value.

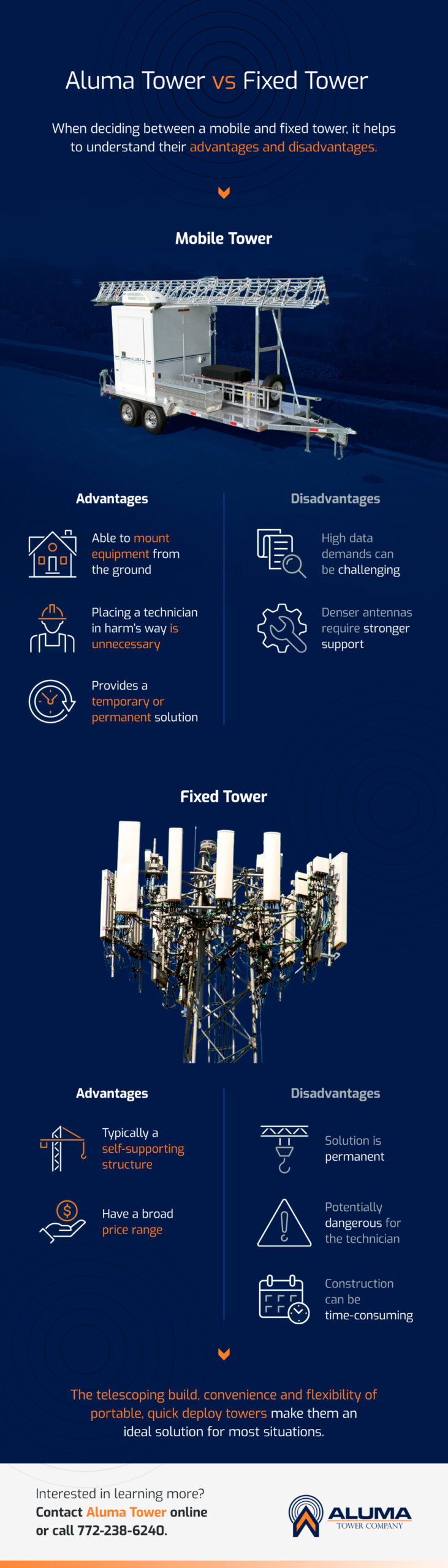

Matching a Tower to Your Purpose

Each organization has varying requirements and operational needs. For instance, an emergency management agency might prioritize a mobile option that rapidly deploys to disaster zones. Meanwhile, a border patrol unit might need a more fixed, high-durability surveillance tower that can support heavy equipment and withstand harsh weather.

Regulatory requirements and future scalability shape your tower investment. Look for a partner that can deliver the customized coverage, reliability and security your industry demands. For mobile units requiring rapid deployment, your provider should design a solution that fits your goals and budget.

Plan Your Tower Project With Aluma Tower

Aluma Tower Company specializes in aluminum telescoping and trailer-mounted towers engineered for rapid deployment and long-term performance. Our solutions are durable, reliable and easy to use.

To get an accurate estimate, request a custom quote tailored to your specifications. We’ll help you design a tower that fits your timeline, budget and operational goals — with the service and expertise you expect.